Taro’s Origami Studio has worked on all kinds of complex projects and installations over the years. Some of them involve brand new origami designs, large-scale construction, computer renderings, or CNC parts, but for this Ashfield Health project to bring awareness to Multiple Sclerosis Taro’s used all of those skills and a few more along the way. The goal for the project was for a fully realized large-scale display that guests could interact with, complete with origami cells. In order to successfully design and create each part of this project, Taro’s and Ashfield Health began talks with the studio over 6 months before the event itself.

Taro’s Origami Studio has worked on all kinds of complex projects and installations over the years. Some of them involve brand new origami designs, large-scale construction, computer renderings, or CNC parts, but for this Ashfield Health project to bring awareness to Multiple Sclerosis Taro’s used all of those skills and a few more along the way. The goal for the project was for a fully realized large-scale display that guests could interact with, complete with origami cells. In order to successfully design and create each part of this project, Taro’s and Ashfield Health began talks with the studio over 6 months before the event itself.

1 – Neuron Design

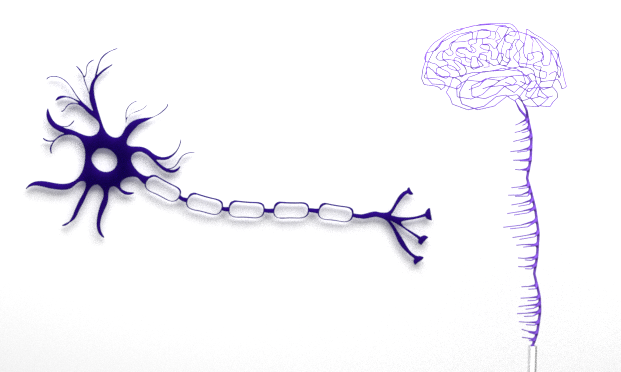

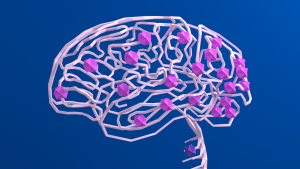

To begin with, Ashfield Health provided some images that they felt would work well to design from. After talking with their team, 2 different design options were floated- one that would use a neuron, and the other that would use a human brain and spinal column. So the Taro’s team set out to design versions of these options to see which ones to peruse further. Below you can see the first round of renderings for the project.

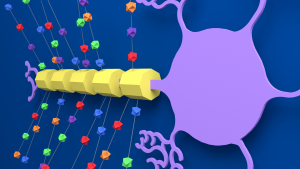

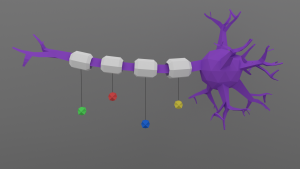

After talking with Ashfield further, some revisions were made to both options. In both cases, the Ashfield team wanted to see what the designs would look like if they were a bit more three-dimensional, so Frank Ling, a Senior Designer for Taro’s fleshed out the myelin sheathes on the neuron (in yellow) and then also thickened the wire-frame structure for the brain on the second option. Next they wanted to see exactly ow the origami cells the guests would fold at the event would interact with the model, so smaller origami balls were inserted as placeholders in the renderings.

In the end though, the large-scale neuron was chosen, and a fully 3D version of the model was created. Once the basic idea of the model was picked, the Taro’s staff worked to integrate origami modeling and construction techniques to establish a final version that could be created out of a material that could survive shipping, installation, and the entire weekend. In this case Taro’s decided to go with custom cut and painted foam core.

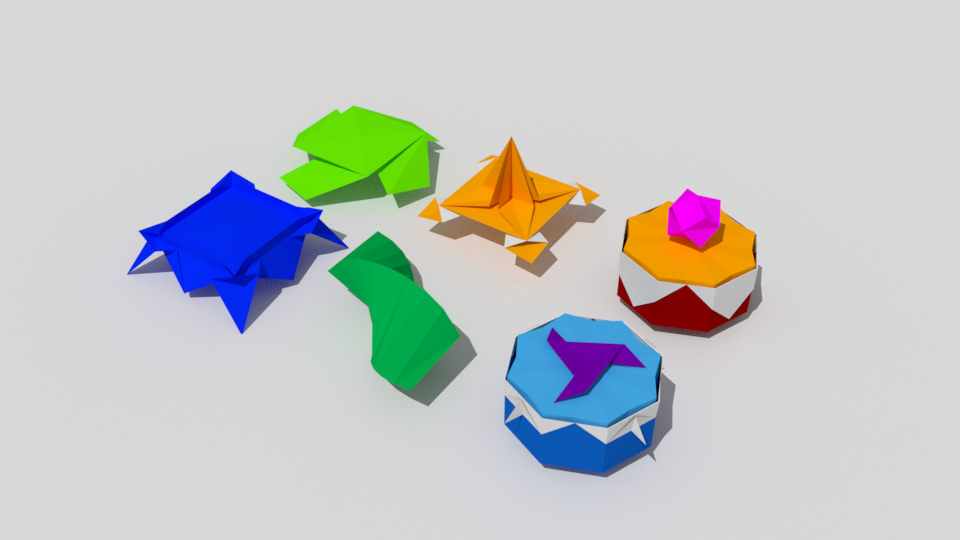

2 – Cell Design

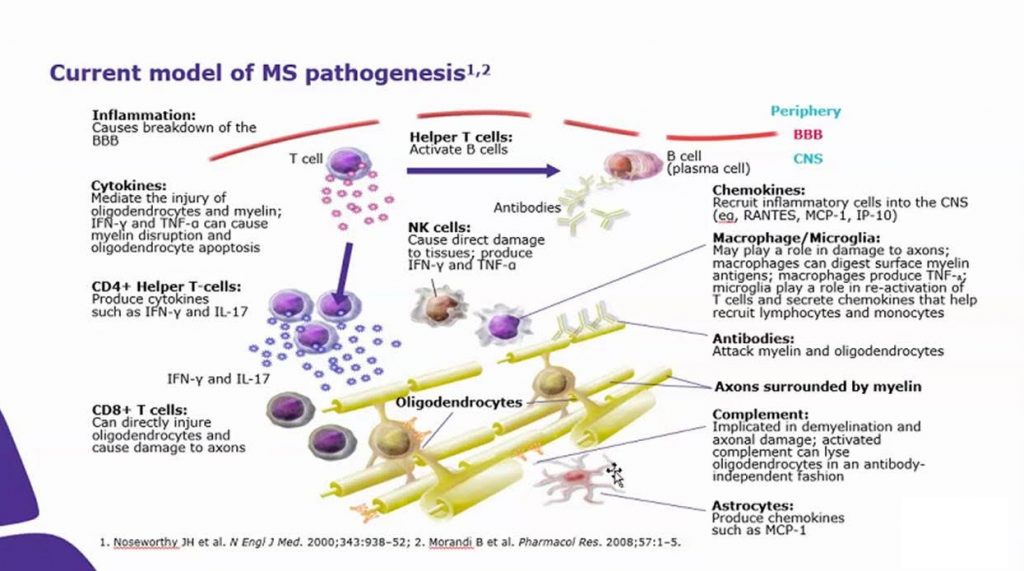

Cell design was the second major part of the construction. The neuron would be the focal point of the display, but the individual cells would be the origami connection as well as the way to draw guests into the booth and have them interact and feel like they had a stake in everything. After another round of brainstorming and talks with the Ashfield Health team the cells were chosen, and origami interpretations of them were created. There was a total of 8 different unique cells chosen, from oligodendrocytes and antibodies to T-cells and cytokines. Each unique design was made to be as realistic as possible so the health professional could create a cell of their choosing and then place it on the neuron in it’s proper position.

Above you can see the source material and below is how each of the cell origami models turned out. See if you can match any of the origami models to their real-life counterpart!

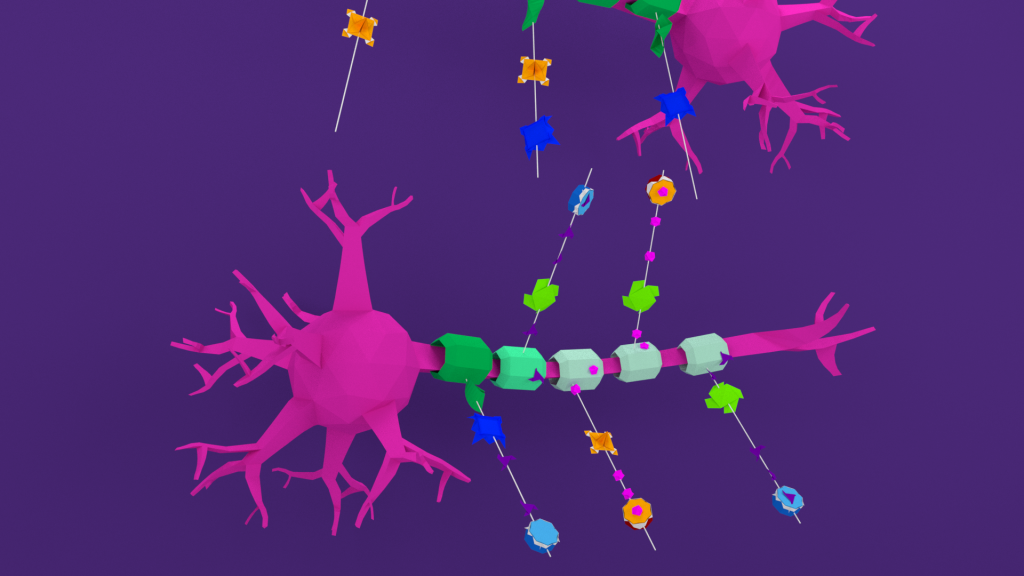

Once the cell models were finished, the Taro’s team needed a good way to attach everything to the neuron, so branches off the myelin sheathes were developed and incorporated into the model. The last touch for the installation was the addition of electrical light pulses going down the myelin sheaths. Here’s a look at the final render Taro’s put together for Ashfield.

3 – Neuron Fabrication & Construction

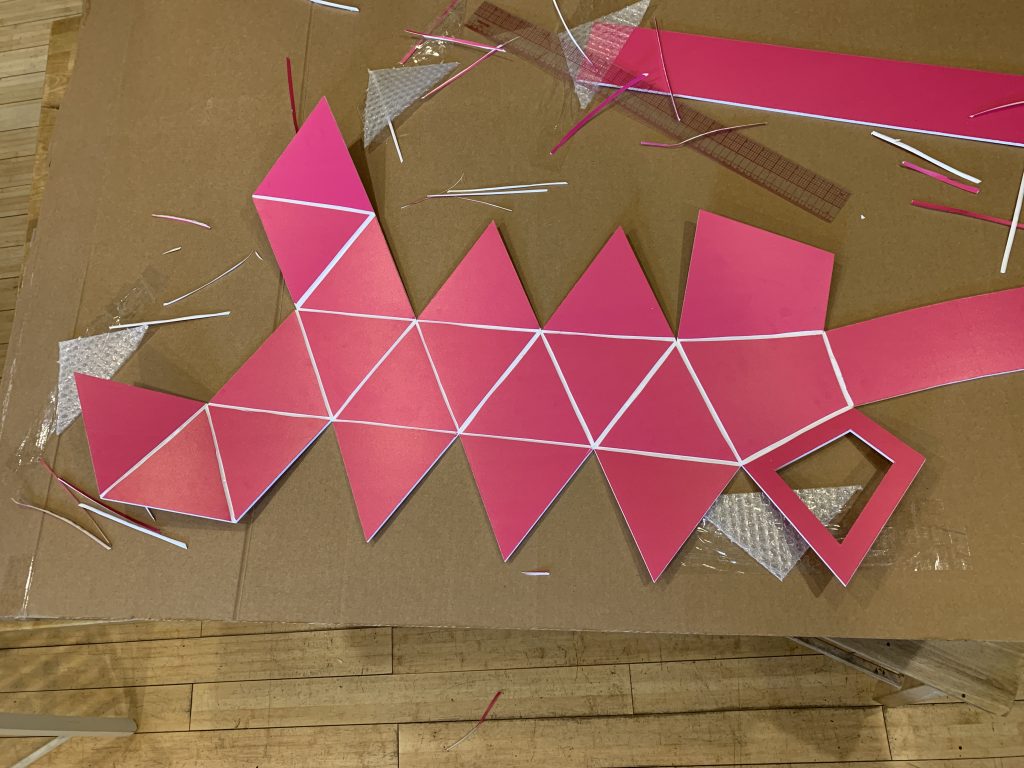

After all of the design work was finished, it was time to move forward and create the neuron. The first step was to take all of the 3-dimensional computer versions of the models and turn then into the flat unfolded shapes so that we could have then CNCed. Using a company out of New Jersey, Taro’s had all of the parts of the neuron printed in custom-colored ink, scored, and cut.

Next was the tedious process of gouging out each and every one of the crease lines in the model so that each panel could fold properly despite the thickness of the foam core material.

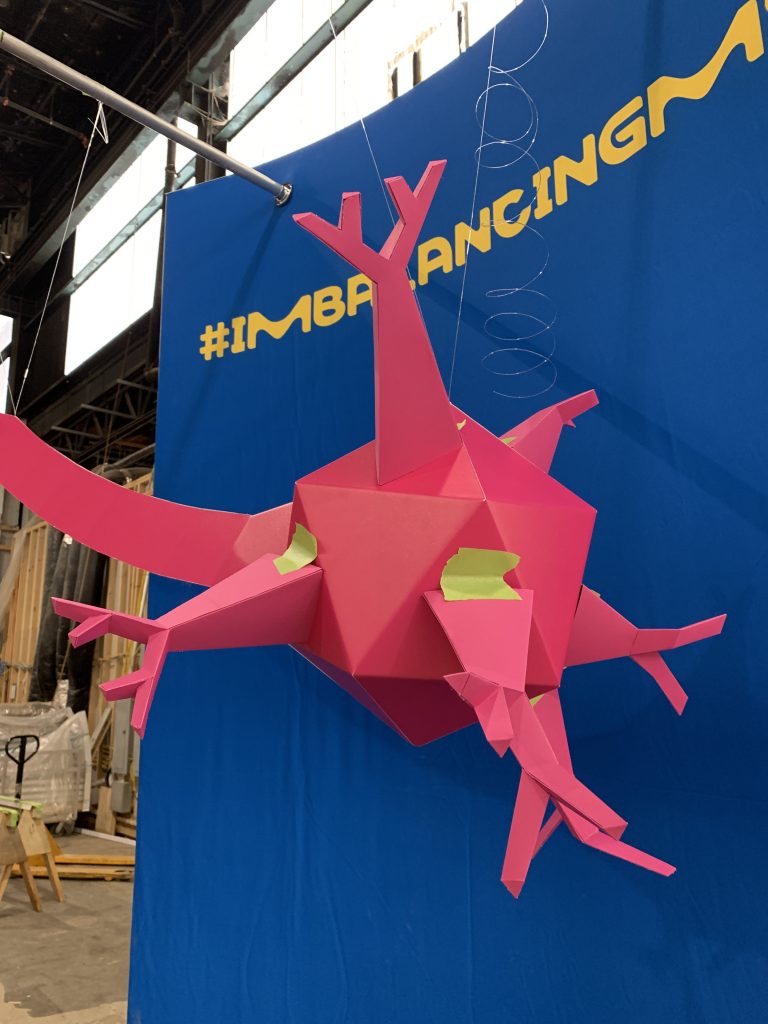

Many hours and time with a glue-gun, drill and hammer later, each of the neuron bodies and tentacles were completed. The Taro’s team also had to design a way for there to be access to every part of the neuron during installation, so you can see a lot of the holes and access panels created as well.

4 – Electrical & Weight Testing

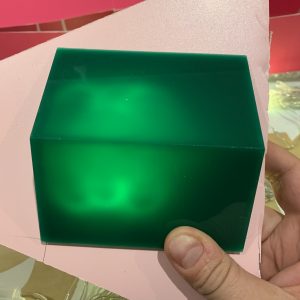

The electrical component of the model proved to be one of the trickiest parts of the entire build. Ashfield Health was interested in an electrical pulse going through the entire sheath of the neuron, but there wasn’t a lot of room for wiring and there also wouldn’t be a place for everything to plug in. So the Taro’s team, headed by Ben Friesen and Frank Ling, found a few battery and remote control powered LED lights that would fit inside the stem of the neuron. They also then had specialty-cut sheets of translucent acrylic made to go over the top of the neuron base.

Then, through a series of remote-controlled settings the team was able to simulate an electrical pulse moving across the neuron.

Shipping and weight restrictions were also a concern for the project, so the whole model was driven by the Taro’s team to the Philly-based home of Ashfield’s design team to test both the rigging of the models and the placement. There were two neurons made for the installation, and in the end the team decided it looked best to have them angling towards each other. The neuron bodies and dendrites were designed to be separated for travel as well so that nothing would be destroyed in transit.

5 – Dallas ACTRIMS Event

Then came the event itself. With nearly 6 months of design, revision, and construction time spent on the project, Senior Artist Ben Friesen was sent to Dallas to install the neurons, teach the staff the models and help everyone fold them throughout the convention. All of the parts arrived safely and installations went along without a hitch.

Here is a final look at the project before all the guests arrived and installed their very own origami cells.

Convention guests from all over the world then tried their hand at the origami cells and installed them on the neuron as they saw fit.

The event was a giant success as the neurons become entirely filled over the course of the week. These neurons were then a wonderful way for people to visualize exactly what happens in the biological process and people really enjoyed having a change to study everything in large-scale.

Finally a check for 10,000 dollars was awarded to a useful charity on behalf of everyone who participated in the event.

Here is one final video of the neuron in all of it’s glory at the end of the event. In the end, Ashfield Health liked the entire installation enough to decide to keep the whole thing and install it at their headquarters. This was certainly a project with many challenges, but the Taro’s Origami Staff proved successful in tackling all of them.